We are proud of our nearly 60% Japanese market share in building locks, and our products

being used in 50 countries around the world is a core business for us.

More than 70 years of experience and know-how in the development of locks, as well as

exhaustive quality management have made MIWA a global brand that can be relied upon,

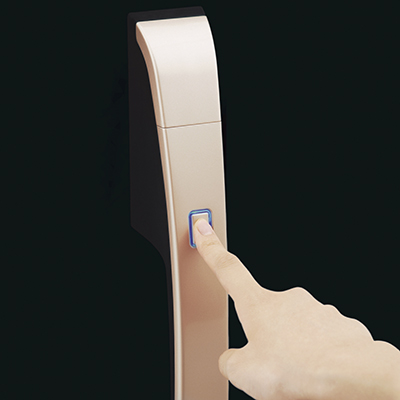

and this has translated into unparalleled support from our customers. Furthermore, recent

years have seen us rapidly introducing cutting edge IT skills and biometrics technologies,

and we are providing next-generation security systems that target future security needs.

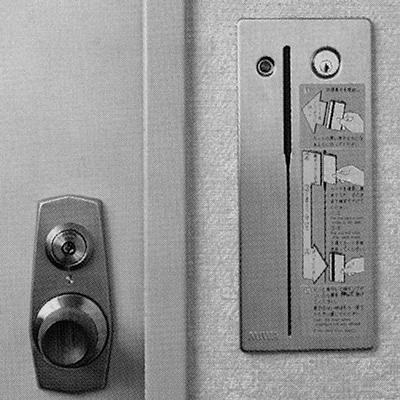

HM series(1955)

DISC cylinder(1957)

EC cylinder(1967)

ALH series(1982)

AL3H series(1988)

TKL series(1988)

U9 cylinder(1991)

PR cylinder(2003)

ALFH series(2004)

LB cylinder(2007)

ALV2 series(2011)

iEL Zero series(2015)

PiACK II series(2017)

DTRS series(2017)

Security changes with the times. MIWA LOCK’s integrated research and development has given us further improved product development capabilities.

We ensure strict quality management through all stages, including design, production, and in specifications. We are building a“ MIWA” brand that can be relied upon.

Only the required quantities of the required products are delivered when they are needed. This has been made possible by our large scale + high-mix, low volume production.

We are moving forward together with regions, the planet, and the future. Our efforts towards the environment are an important issue for MIWA. “MIWA LOCK Tamaki Plant” ISO14001 certified